Custom Metal Parts

Offer Exclusively Customized Product Services

01

Ready the design blueprint or sample.

02

We offer a price quotation according to the provided drawing or sample.

03

Once the price is approved, commence sample fabrication.

04

After approving the sample, confirm contract details and pay the deposit.

Custom

Flow Chat

05

Initiate mass production.

06

QC team checks for flaws, tests dimensions, function, look.

07

Send invoice. Offer safe pay ways. Settle the remaining payment.

08

Package well, label, load. Dispatch the consignment

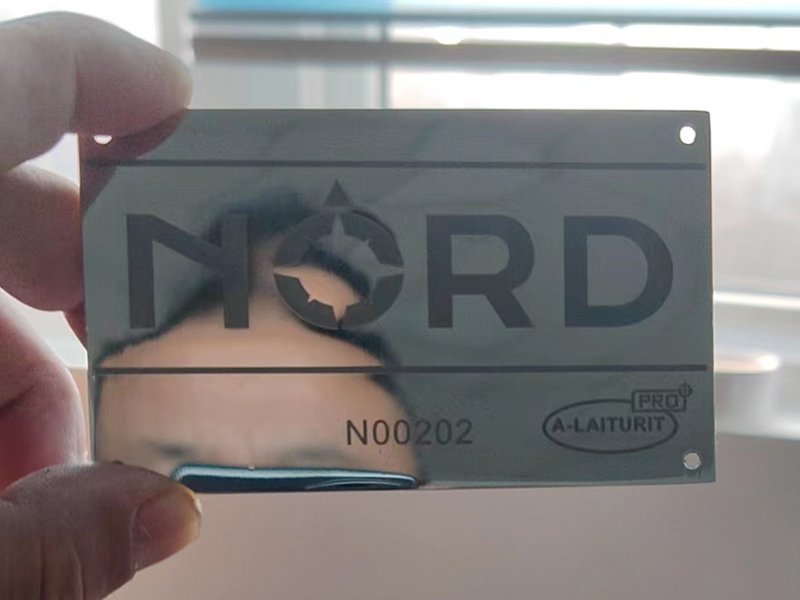

Custom Creations

Our offerings extend beyond what’s pictured. We can craft similar products for diverse applications. Every product is bespoke, tailored to your exact needs. Simply forward drawings or sample images, along with details such as material, material thickness, dimensions, surface finish, and quantity. We’ll swiftly present you with an optimal quotation. If you have queries or seek further product insights, feel free to get in touch without delay!

You might find the following form useful, which encompasses, among other things.

| Product Type | We specialize in customizable products, adaptable to your unique needs. |

| One-Stop Service | From die/mould R&D, prototype making, through mass production, inspection, surface treatment like painting, electroplating options, packing to delivery – we handle it all. Processes involve sheet metal work (fabrication, stamping, laser cutting, bending, deep drawing, welding etc). |

| Materials | A broad selection including steel types (mild, carbon, spcc, galvanized, stainless), aluminum, copper, brass and alloys. |

| Dimensions | Made to match your drawings or samples precisely. |

| Finish | Multiple choices such as painting, zinc plating (electrogalvanizing, hot dip), powder coating, electrophoresis, anodizing for different looks and protection. |

| Application Area | Spanning across automobile, agricultural, engineering, construction machinery, plus garden, environmental protection, ship, aviation sectors, also pipe fittings, hardware tools, toys, electronics parts – essentially various industries’ spare parts needs. |

Product Type

We specialize in customizable products, adaptable to your unique needs.

One-Stop Service

From die/mould R&D, prototype making, through mass production, inspection, surface treatment like painting, electroplating options, packing to delivery – we handle it all. Processes involve sheet metal work (fabrication, stamping, laser cutting, bending, deep drawing, welding etc).

Dimensions

Made to match your drawings or samples precisely.

Materials

A broad selection including steel types (mild, carbon, spcc, galvanized, stainless), aluminum, copper, brass and alloys.

Finish

Multiple choices such as painting, zinc plating (electrogalvanizing, hot dip), powder coating, electrophoresis, anodizing for different looks and protection.

Application Area

Spanning across automobile, agricultural, engineering, construction machinery, plus garden, environmental protection, ship, aviation sectors, also pipe fittings, hardware tools, toys, electronics parts – essentially various industries' spare parts needs.

3000t

Monthly/Annual Production

Huixin Industry

Your Premier Partner in Industrial Equipment Solutions

Our products are well-received in the US, Germany, Italy, Finland, the Czech Republic, and Japan. With a monthly capacity of 3,000 tons and annual output to match, we serve international clients promptly.

Why Choose Us?

Our Distinctive Advantages

Low MOQ

We accommodate diverse project scales with a low minimum order quantity.

Renowned Brand Collaboration

Proven experience working with major brands, enhancing our quality and performance standards.

Stringent Quality Control

A strict system monitors every production stage, ensuring top-notch products.

Efficient Factory

Large-scale facilities ensure short lead times and stable quality.

Certifications

Holding relevant certifications for international compliance.

Non-standard Expertise

Specialize in custom steel structure fabrication.

FAQ

How To Get The Quote?

Please email your drawings with format PDF, stp, step to us, and tell us the material, quantity and surface treatment , after our engineers review,we will make a quotation to you ASAP.

Can I Order Just One Or Two Pcs For Testing?

Yes, of course.We have experience in making a prototype or sample

Can You Produce According To The Samples?

Yes, we can produce by your samples.

How Long ls Your Delivery Time?

7~ 15 days, depends on the order quantities and product process.

How Do You Make Our Business Long-Term And Good Relationship?

1. We keep good quality and competitive price to ensure our customers benefit.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.