In today’s highly industrialized and customized manufacturing landscape, metal parts customization has become an essential service for numerous industries. Whether it’s for automotive, aerospace, machinery, or other sectors, the demand for precisely engineered and uniquely designed metal components is constantly on the rise. Our company is dedicated to providing top-notch metal parts customization services, and here is a detailed introduction to our order consultation and placement process.

Table of Contents

Toggle1. Preparation of Design Drawings or Samples

The first step in the metal parts customization process is to have a well-prepared design drawing or an actual sample. The design drawing should clearly illustrate the dimensions, shape, and any specific details or requirements of the metal part. If providing a sample, it should be in a condition that allows our team to accurately assess and understand the intended final product. This initial preparation is crucial as it forms the foundation for the entire customization project.

2. Quotation Based on Drawings or Samples

Once we receive the design drawings or samples, our professional team will conduct a detailed assessment. We will take into account various factors such as the complexity of the design, the type of metal required, the manufacturing techniques involved, and the estimated production volume. Based on this comprehensive evaluation, we will provide a precise quotation. The quotation will include all relevant costs, such as material costs, processing fees, and any additional charges for special requirements or finishes.

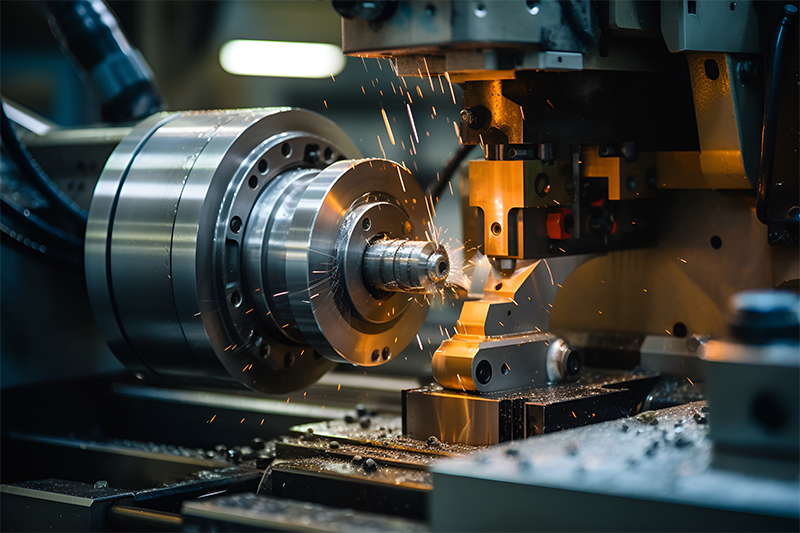

3. Sample Production after Price Acceptance

After the customer accepts the price we have offered, we will commence the sample production process. Our experienced technicians and engineers will use advanced machinery and techniques to ensure that the sample closely matches the design specifications. During the sample production, strict quality control measures will be implemented to monitor and maintain the quality and accuracy of the sample. This step allows the customer to have a tangible preview of the final product and make any necessary adjustments or modifications.

4. Confirmation of Contract Details and Down Payment after Sample Approval

When the customer is satisfied with the sample, we will move on to finalize the contract details. The contract will clearly define the scope of work, including the quantity, quality standards, delivery time, and payment terms. At this stage, the customer is required to pay a down payment as per the agreed-upon terms. The down payment serves as a commitment from the customer and also helps us to initiate the full-scale production process.

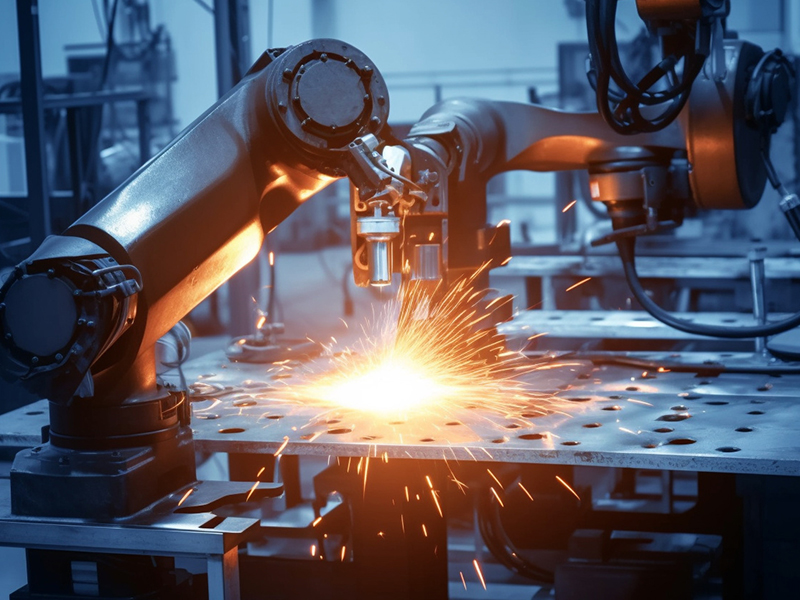

5. Commencement of Mass Production

With the contract details confirmed and the down payment received, our production team will start the mass production. We have a well-equipped manufacturing facility and a skilled workforce that can handle various types of metal parts production. Throughout the production process, regular quality checks will be carried out to ensure that each metal part meets the required quality standards. We adhere to strict production schedules to ensure timely delivery of the final products.

6. Quality Inspection before Shipment

Before shipping the finished metal parts, a comprehensive quality inspection will be conducted. This inspection will cover aspects such as dimensional accuracy, surface finish, mechanical properties, and any other specific quality requirements. Any defective or non-conforming parts will be identified and either reworked or replaced. This final inspection step is essential to guarantee that the customer receives high-quality metal parts that meet their expectations.

7. Payment of Balance

After the quality inspection is successfully completed and the customer is informed of the readiness for shipment, the customer is required to pay the balance of the payment. This final payment clears the financial obligation for the order and allows us to proceed with the shipping arrangements.

8. Shipment

Once the balance payment is received, we will arrange for the shipment of the metal parts. We work with reliable shipping partners to ensure that the products are delivered safely and on time. The customer will be provided with the shipping details, including the tracking number, so that they can monitor the progress of the shipment and expect the arrival of their customized metal parts.

By following this streamlined and efficient process, we strive to ensure a seamless and satisfactory experience for every customer seeking metal parts customization. Our commitment to quality, precision, and on-time delivery is unwavering. We look forward to collaborating with you and bringing your metal part design concepts to life, contributing to the success and innovation of your projects.